The high level update on my PyCon talk prep is that I’m currently making the transition from making steady deliberate progress to a more panic-driven hair-on-fire style of working. Three weeks from today this thing better works–on stage, and in Portland.

On a more technical level, the status is that I have a working prototype of my demo and am confident that I can construct a good talk narrative around it. Here’s what the prototype currently looks like (cat for scale):

An obvious next step is to put together a frame to make the setup ready for transport, and to make it look nice. I loathe this step in any project. It’s technically so insignificant, yet there are so many options and so much room for small mistakes.

My first idea was to get two plywood plates as base plate and top cover. Bolt down all the pieces of the demo, attach some perforated angle metal at the corners, and Bob’s your uncle. Except: I don’t have tools for making neat straight cuts in our little city apartment, and no store in the entire town of San Francisco seems to be interested in cutting two pieces of 24in by 16in plywood to size for me.

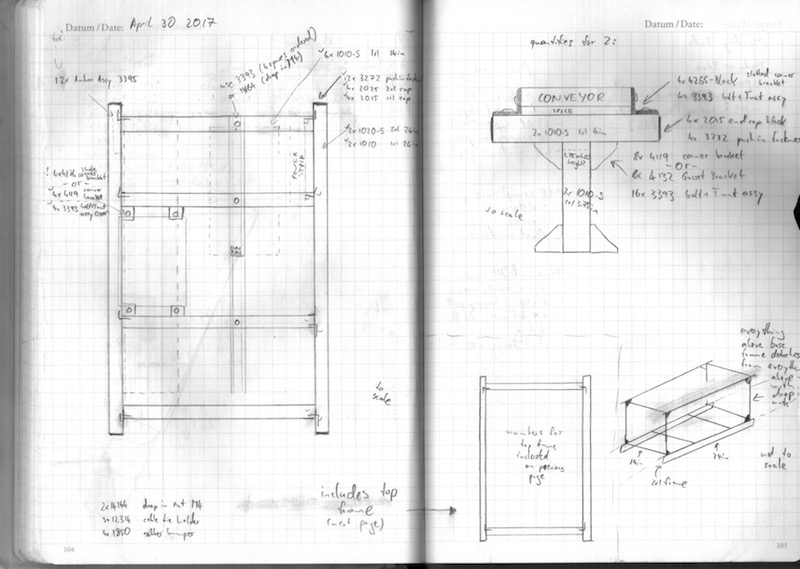

Wood being annoying and not very factory-like anyway, I dropped that plan and sketched out a frame made of aluminum extrusions, a.k.a. 80/20. Aluminum extrusions are a common sight in factories anyway, and you can order components cut to size, making it the “Industrial Erector Set” their logo advertises. Keeping track of all little connectors, nuts and bolts is tricky, but I’m keeping my fingers crossed that this sketch was detailed enough to compile a full bill of materials:

This was my first time ordering a project bill of materials from 8020.net, as opposed to having some stock and cutting tools at work. A few things I learned:

- The 8020.net website isn’t fancy but extremely usable for exploring the catalog and machining options

- This stuff is expensive! My 24in x 16in x 8in frame clocks in $300 including fixtures for the conveyor, cable tie holders, etc.

- Internal fasteners are both stronger and cheaper than external fasteners after accounting for machining or hardware required, respectively.

With this order I also hit the first logistics glitch during this entire project. 80/20 (the company) has switched to a new internal software just this week and, as these things go, the transition wasn’t flawless. “Expect your order to be delayed by a day or two,” the customer support chat person said, implying that I’ll be waiting for at least 10 days including shipping.

Wish I had known that earlier, [insert title of this post here for silly joke]